Industrial Furnace Manufacturing and Combustion Services

Our team is skilled in all aspects of an industrial furnace system including new builds, retrofits, installations, controls, troubleshooting, inspections, and training.

Combustion Solutions

When it comes to furnaces and combustion, ONEX is your trusted partner. Whether you need help with a New Design, retrofit, or individual components such as controls, burners, valves, orifices, controllers, flame safeties, relays, push buttons, or starters, our team has the expertise and over 50 years of experience bringing the heat.

Our in-demand combustion experts build, maintain, and repair custom combustion systems, providing long-lasting solutions for your furnace needs.

Why Choose Onex for Your Combustion?

One of the key and unique benefits of the Onex team is that we employ the specific talents required to handle all aspects of the in-house build.

This allows one purchase order, one contact, and allows projects to move seamlessly from concept to completion.

For after completion support, Onex has dedicated service experts trained in troubleshooting and inspections.

Get your Forge and Heat Treat Furnaces operating at peak performance by our expert Combustion Systems technicians. Onex, Inc.'s Combustion Services include upgrades and controls, inspection, and training.

Preventative Maintenance

In order to reduce unplanned downtime, our technicians provide preventative maintenance on your combustion system to maximize efficiency. Routine maintenance ensures all combustion systems and panel controls are fully functioning which decreases the chances of lost production time, operational costs and, most importantly, ensures the furnace is operating safely.

Inspections and Survey Preparation

Inspections check gas lines for leaks, clean valves ensuring proper airflow and adjust the air-fuel ratio as needed. Our technicians will provide a spare parts list and document recommended repairs or upgrades. Our team will help setup for a survey, making any required alternations

Combustion and Controls Upgrades

Our combustion service team can upgrade your system to save energy, meet current NFPA86 regulatory compliance, and increase productivity.

Whether you require a system upgrade or a complete retrofit, Onex will work with you to select the most effective solution for your unique needs and operation. To meet your safety and operational requirements, our control panels are based on your specific equipment and plant networking requirements.

Custom Training For Furnace Operators

Education is important, knowledge is key. With any industrial furnace, knowing how to properly operate, maintain, and troubleshoot allows the customer to operate with autonomy and allows your team to communicate effectively with Onex.

Whether in person, or remote, Onex personnel can provide tailored training solutions on a vast number of topics. Combustion 101, safety, controls, refractory and furnace operation are just a few of the sessions we have provided.

Engineered Preheating Systems for Molten Metal Handling

Preheating your ladles, troughs, tundishes, and other molten metal handling products can make or break your operations’ throughput.

Our in-house team of combustion experts designs burners and combustion systems that create an even, fast heat inside the ladle.

Our Industrial Furnace Combustion & Engineering Work

Furnace Control Panel

Heat Treat Furnace Combustion Piping

Inside A Control Panel

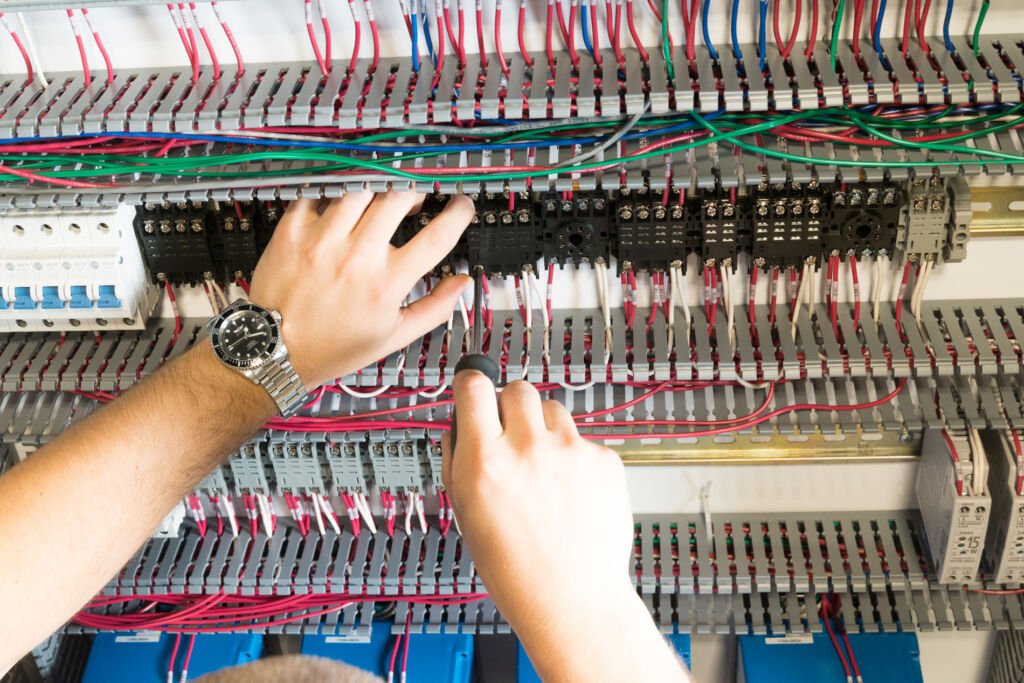

Wiring A New Control Panel

Furnace Control Panels Installed

Zinc Melter Combustion Piping