Refractory Design, Build, Installation & Repair Services

Industrial Furnace Refractory work requires a high level of expertise and craftsmanship to ensure it's done right.

Construction Solutions

With our Construction and Combustion division, we are excellently positioned to meet your specific refractory construction needs.

From the high-quality materials we use to the proprietary process our masonry experts implement, to our respected service record, we continue to burn bright as the industry standard for refractory design, construction, retrofit, demolition, and repairs.

Why Choose Onex for Your Construction?

The physical capacity of our new division allows us to streamline more of our processes, applying Lean principles to eliminate waste and inefficiencies, accelerating turnaround times so you are up and running faster.

We have even more capacity to work on parallel projects and with our one-stop-shop solutions for construction, combustion and fabrication, we’ve got every phase of your furnace project covered.

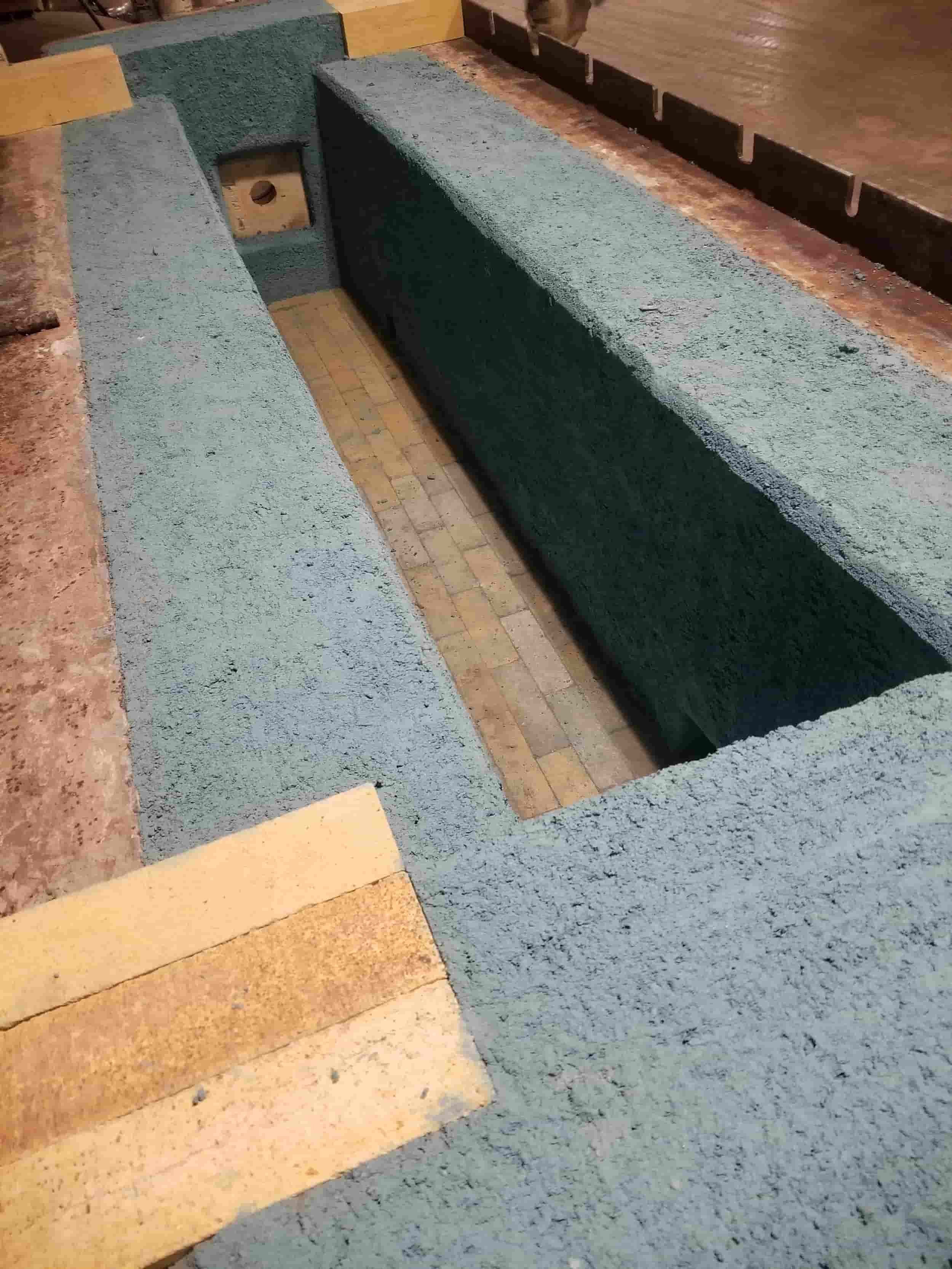

From casting, raming, fiber, brick and everything else in between, we are THE go-to refractory design, build, and installation professionals. We also use our next-level masonry skills to provide refractory service, repairs, retrofit, and demolition.

Design & Engineering

Onex, Inc.’s design team will engineer your refractory lining based on your specific needs. We make sure to accommodate all safety, environmental, and operating factors. Give us your lead time and budget, and we’ll create the right solution for your refractory.

Demolition Duty

Make sure your demolition goes smoothly and safely! Onex, Inc. offers quick and well-managed demolition services. We choose the best and most efficient equipment for the job. Tell us your time and budget constraints, and we’ll build a demolition solution to match.

Professional Installation

From casting to shotcrete and everything in between, we are the industry’s go-to refractory installation professionals. Our craftsmen’s masonry skills are on fire. We expertly install whatever refractory material will best suit your application. Refractory materials include ceramic fiber and many different firebrick linings.

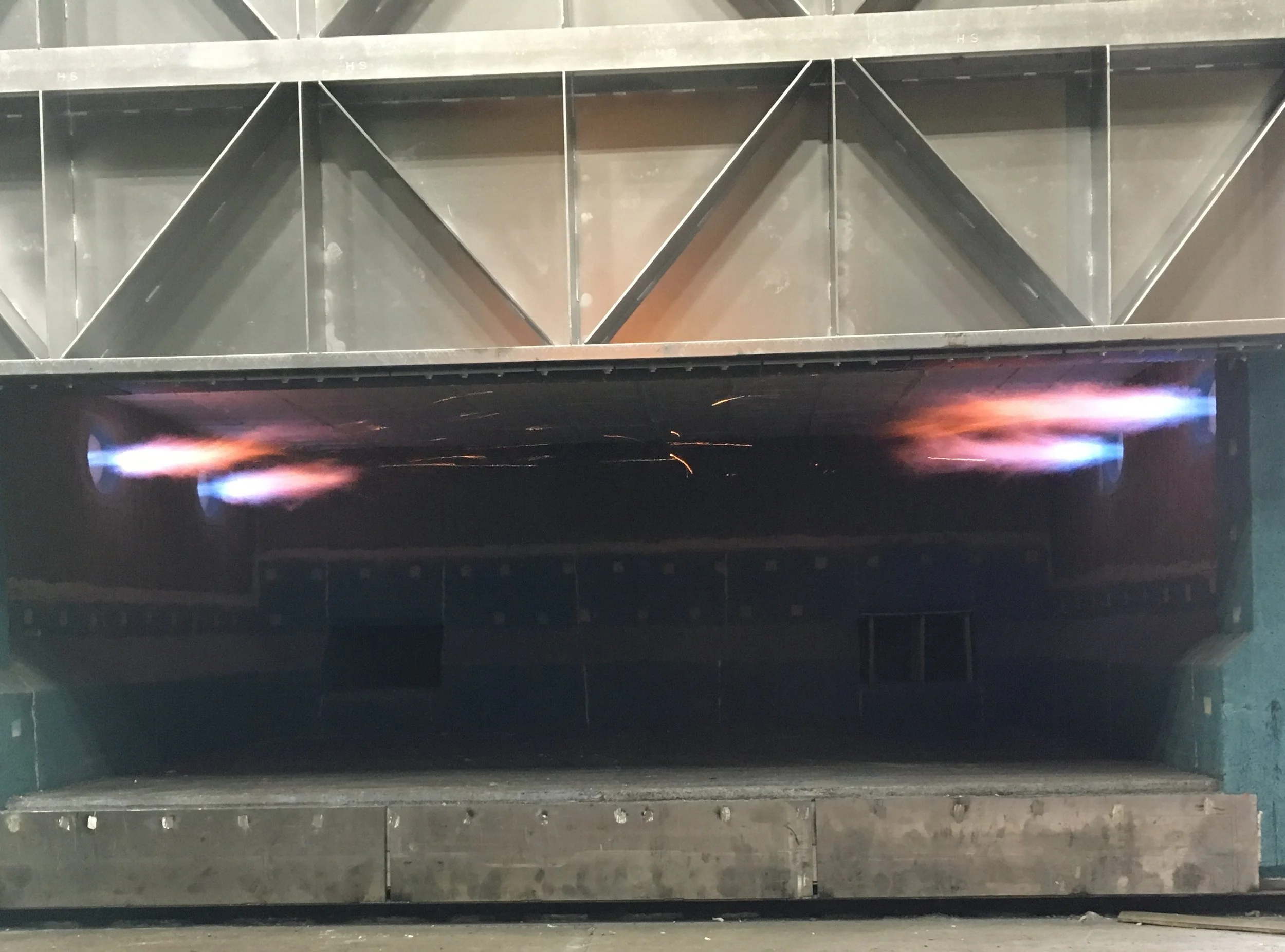

On-Site Dry-Out

We offer on-site dry-out services when the refractory installation is complete. Your furnace must be properly cured and up to operating temperature before use. Our expert installers adhere to an exact dry-out schedule and document it using a chart recorder.

Refractory Installation Services Photo Gallery

Aluminum Holder Reline

Detrick Lintel

Forge Furnace Reline

Regenerative Thermal Oxidizer Reline

RTO Media

Regenerative Thermal Oxidizer Lid

Ceramic Fiber Lined Heat Treat Furnace

Reskin Forge Furnace

Ladle Cover

Roller Hearth Furnace Reline

Ram and Brick Furnace Reline

Form and Pour Castable

Brick Kiln Reline